Higher visibility with the R-Series

New design

New design

The design of the R-Series Loaders increases the visibility of the implement at no matter what lift height the loader is placed. With its curved shape, the loader boom is aligned with the tractor hood and provides a better view when working with the loader. The position of the mechanical leveling link supports the higher visible level of the mechanical self-leveling (MSL). Due to the compact design of the boom and the cylinders, the raised distance of the cylinders to fenders guarantees sufficient clearance. This allows an appropriate steering angle to maneuver the loader in tight spaces.

The low position of the torque tube also allows good visibility and clearance for the tractor’s front lights, which provides an ideal lighting solution for night time use.

Loader lights

Front loader lights increase the visibility

Front loader lights increase the visibility

Operating at dusk or night is a part of a producer’s working life. The increased visibility allows the operator to drive in a more comfortable and confident way. The loader lights are mounted on the loader boom and follow the loader movements. With 850 luminous flux per light, the light provides a powerful illumination to support working in dark conditions. The loader lights show a low power consumption of 15 watts per lights.

Comfort on the R-Series

Suspension

Location of the loader suspension

Location of the loader suspension

Loader suspension button on the mechanical joystick

Loader suspension button on the mechanical joystick

The loader suspension option further improves comfort when using the R-Series Loaders on uneven terrain. The gas accumulator is integrated and protected in the torque tube. The suspension is activated from the driver seat due to a button on the mechanical joystick (1) or a switch on the console with the electronic joystick. The loader suspension results in a smoother ride and less potential material loss.

Please go to loader suspension for more information.

Gear Shift Switch (GSS)

Mechanical joystick with GSS

Mechanical joystick with GSS

The gear shift switch (GSS) (1) on the joystick allows the operator to change the gears without moving the hand away from the joystick. During the loading process, different speed levels are required to operate quickly and efficiently. The GSS option is installed on the joystick. It is available for all loader models.

Please go to the GSS for more information.

Rollback bundle

Increased rollback angle

Increased rollback angle

With the rollback bundle, the operator can increases the rollback angle by 12 degrees and guarantees reduced material losses. Consequently, more material can be moved in one load which can help to reduce the number of loads and save time during loader operations. The implement parts have to be installed on the lower end of the bucket, where the implement is connected to the carrier frame.

Please go to the rollback bundle for more information.

Hydraulic implement unlatching (HIU)

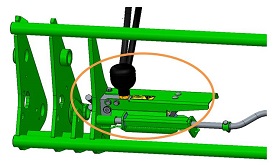

Gas accumulator to operate the HIU

Gas accumulator to operate the HIU

In base, all R-Series Loaders are equipped with a Euro carrier, which allows connection to all Euro implements to the loader, no matter which manufacturer provides the implement. The Euro carrier is delivered in base with an automatic implement latch (AIL).

The Euro and Combi Euro/Sms carrier can be equipped with the hydraulic implement unlatching option which greatly enhances the operator’s comfort, because it allows unlatching the implement by simply pressing a button from the operator’s station. There is no need for the operator to get out of the cab to remove the handle on the implement.

A gas accumulator is filled with oil when crowding the implement. To activate the device, the two switches installed in the right-hand side of the operator’s station are pressed simultaneously by the operator. This action releases the oil, and the implement is unlocked. Compared to competitors, it is still possible to unlock the implement manually.

Please go to the hydraulic implement unlatching for more information.

Electronic self-leveling (ESL) packages

View of the RTP display

View of the RTP display

To make repetitive loader tasks easier and more accurate, John Deere now offers return-to- position (RTP) option which automatically returns the front loader to a preset position. The RTP is part of the ESL packages: the ESL standard package includes the non self-leveling (NSL) boom with RTP, whereas the ESL premium Package provides the mechanical self-leveling (MSL) boom equipped with RTP.

With RTP, the driver can save up to four implement positions: four implement heights and four implement angles. Due to the RTP, productivity can be significantly increased and provides an easy environment for the operator. This function removes the need to keep full concentration on the attachment position; the tractor can manage the loader thanks to a few clicks by the driver. For example, the driver can save four positions in a loading process. The operator loads manure: he takes up the manure (A), transports it to the trailer (B), lifts it above the trailer (C), dumps it into the trailer (D). He can return to all these positions by clicking the joystick in the appropriate direction. Due to the saved positions the risk of damages are minimized.

With the RTP option, there is no need to check the loader height and the implement angle when handling pallets, silage bales, wood, and gravel — the tractor takes the control. This means a complete loading cycle can be performed in 8 movements of the joystick. The electronic joystick and the intuitive CommandCenter™ controls further increases ease of usability.

Please go to the electronic self-leveling (ESL) packages for more information.