Introducing the large H Series. A new standard for logging.

H Series forest machines

Imagine a production system that not only drives productivity but also creates a lasting legacy for generations to come. With the large H production system, we take productivity to new heights.

The new, large size-class H Series harvesters and forwarders demonstrate higher productivity with significantly lower fuel consumption, better stability and improved operator ergonomics.

PRODUCTIVITY

By integrating new automation and real-time connectivity, our production system enables seamless communication and collaboration between human and machine, freeing up valuable resources and propelling businesses towards unparalleled success.

Increased productivity gives you flexibility for the rough weather conditions. What if you could complete a year’s production in less time? What would you do? A holiday? Maybe less machines? More or less of what is up to you.

More productivity with less fuel

Frame lock, high performing engines and improved hydraulics improve drivability and provide increased productivity with less fuel per m3 harvested.

New hydraulics with three dedicated pumps offer more hydraulic power and higher work pressure for feeding. The system is optimized and ensures a balanced fuel economy.

Automation and intelligence as standard

Intelligent Boom Control IBC becomes a standard feature in our large H Series harvesters, and IBC 3.0. becomes a standard feature in H Series forwarders.

Intelligent Cabin Key is a personal remote key to unlock the machine door and open the PC and TimberMatic control system with operator-specific settings. When the operator opens the door lock remotely, the machine is powered, the PC is started and the approach lights are lit automatically. The operator can just start the engine and the machine is ready to work.

Stronger booms

New booms have increased lift and slew forces. They offer more power and longer boom reaches.

The new H7 boom for harvesters offers approximately 10% more lift power and slewing torque. The new H9 boom also has the same 10% increase in lift power, and the slewing torque is 5% more than in the previous model.

The F10 forwarder boom has a new longer reach of 10.2 meters. The corresponding longer reach in the F9 boom is 10.7 meters. The hydraulic hosing and hose routings have been improved. The new F10 is the strongest forwarder boom in the market. With the 40% increased boom lift torque and 22% higher slewing torque, larger grapple options become available.

More stability with frame lock

The cylinder-operated frame lock makes our machines steady in all terrains and enables excellent stability while working with the boom sideways, offering the operator a large working area. Confident and stable working with the cylinder-operated, strong frame lock and maximized stability with the optional active frame lock.

JOY OF WORK

We understand the value of minimizing fatigue and preserving energy for what truly matters.

From intuitive interfaces to ergonomic designs, and from a quiet cabin to accessible service points, every aspect is crafted to enhance the operator’s experience and ease of use.

Ease of use

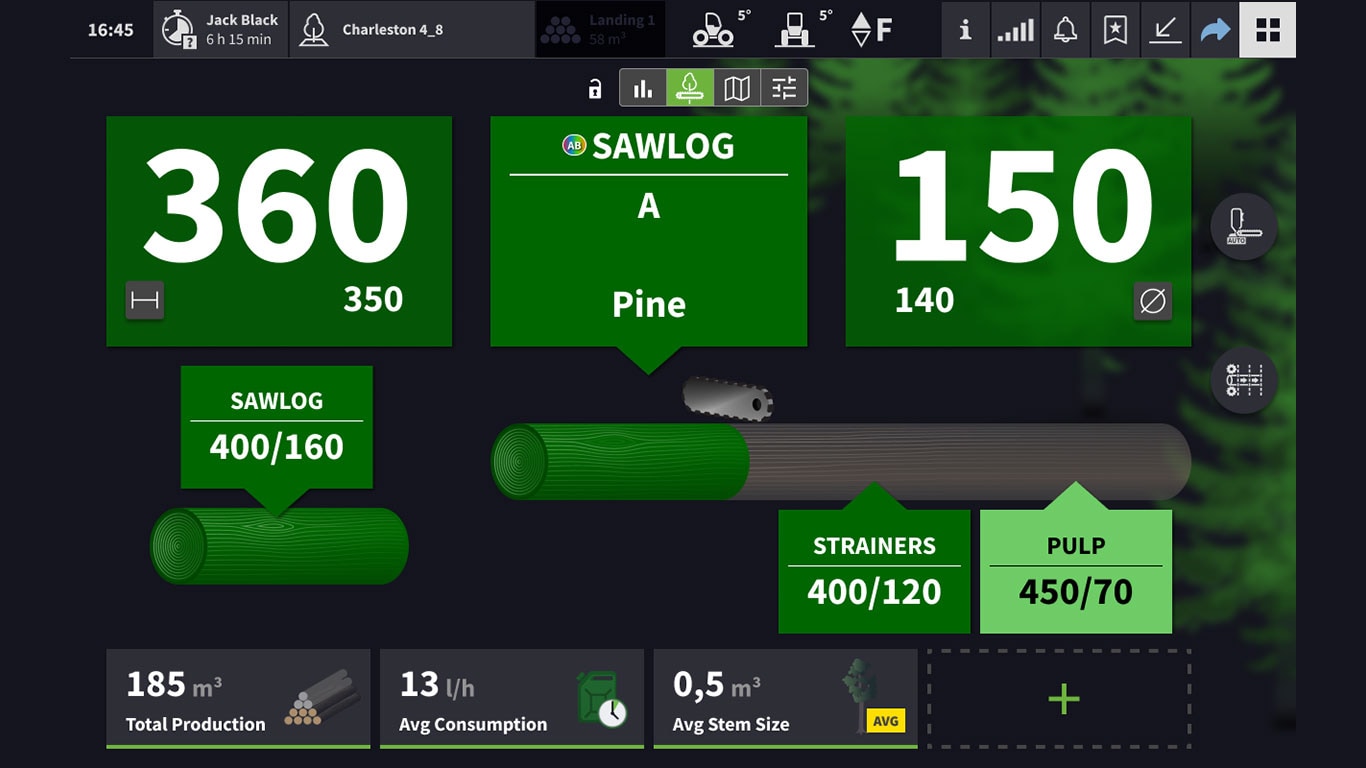

The TimberMatic H control system with the integrated TimberMatic Maps helps the operator achieve superior performance and productivity.

TimberMatic H automation offers ease of use and improved ergonomics. The new interface is simple and easily accessible. The H automation system creates a consistent user experience across all forestry products. The new visualization includes options for night and daylight view. And the on-screen view only shows the info relevant to the situation.

Cabin comfort

The rotating and levelling cabin becomes standard in the large H Series. The cabins have an excellent view to the working area, an improved climate control system and a ±30° increased cabin turning angle. Better lights, lower noise level and more storage space for the operator. A new secondary display for base machine functions and cameras, multiple charging outlets, a new pedal for selecting the drive direction, a new premium audio system with subwoofer and treble speakers.

Intelligent Boom Control IBC and button joysticks

With IBC, boom control is precise, fast and easy because the operator can focus on controlling the grapple rather than the boom joint movements. IBC improves work safety and makes the work easier.

Configurable button joysticks in harvesters make the everyday work easier.

SERVICEABILITY

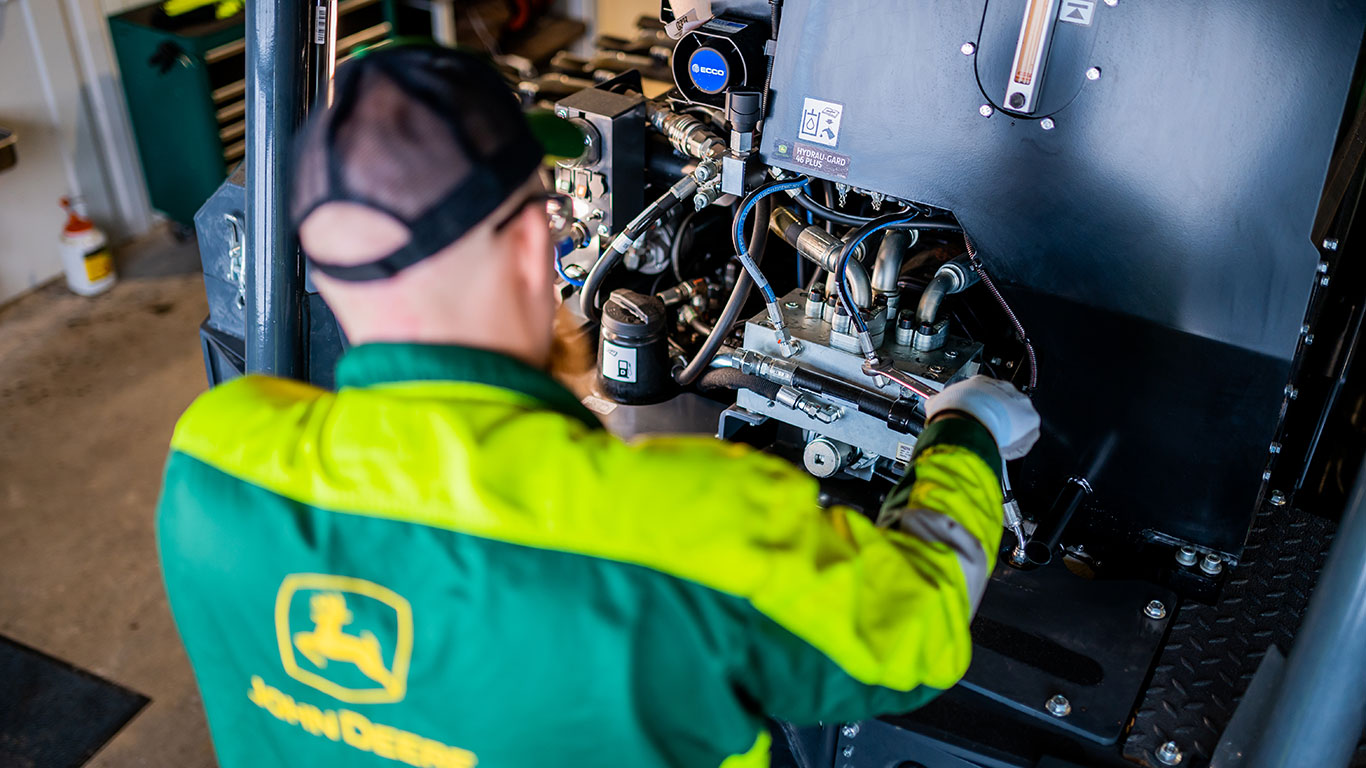

Serviceability is at the core of our production system. We’ve incorporated modular designs and easily replaceable components to make maintenance and repairs simple. Not only does this reduce downtime and costs, it also minimizes environmental impact, contributing to a sustainable future.

Easier daily maintenance

Daily servicing is made easy. The liquid inlets are all located in the same easily accessible place. All machines have electric engine oil level sensors and a totally new central greasing system for ease of use. There are also several practical storages around the machine.

Improvements in serviceability

Fewer individual service tasks and centralized, easily accessible service points make it easy to service the H Series machines. Optional automatic lubrication and central greasing save time. The engine oil level check is automatically visualized on the TimberMatic screen on start-up.

Up to 1000h service intervals

Up to 1000h service intervals with a service contract and a shorter service time means less downtime and lower costs.

PROTECT YOUR PERFORMANCE. PROTECT YOUR TIME. PROTECT YOUR COST.

Three service plan options

John Deere offers three service plan options for H-series machines, with intervals of 500 hours, 750 hours, or 1000* hours. Our new 1000-hour service plan stands out as the best in the market, allowing for less time spent on servicing and lower operating costs. This achievement reflects our unwavering commitment to continuously improving our machines.

By opting for the 1000-hour service plan, you can convert the saved service time into increased production and higher earnings. However, please keep in mind that utilizing the extended 750-hour or 1000-hour service plans requires meeting certain requirements:

- Signed service agreement

- Usage of low sulfur fuel

- Usage of original John Deere oils, filters and parts

- Following the John Deere oil analysis program

Following these guidelines will help ensure optimal performance and longevity for your H-series machine.

*Available only for H Series Machines

John Deere ProtectTM

John Deere Protect is an enhanced service agreement offering for John Deere forestry machines. It maximizes the reliability, uptime, and performance of your equipment. With three tailored maintenance plan options featuring service intervals of 500, 750, or 1000* hours, John Deere Protect ensures your machines are always operating at their best. A service agreement can be set up for new machines or used machines.

Customize your agreement with optional services like Extended Warranties, Performance Optimization Services, Parts Programs, Oil Services, and more to meet your specific needs and logging conditions. With John Deere Protect, you can take full advantage of John Deere expertise, tools, and the latest technical solutions. Enjoy peace of mind with predictable service costs that include labor, genuine John Deere parts, and fluids. Machines with a documented John Deere Protect service history also have a competitive resale value.

John Deere Protect service agreement brings better productivity, lower daily operating costs, and predictable maintenance costs, all with the joy of work.

*Available only for H Series Machines

Harvesters 1270H and 1470H

New hydraulics with three dedicated pumps offer more hydraulic power and higher work pressure for feeding. The optimized system ensures a balanced fuel economy. The new Active Frame Lock brings more stability, whether working on steep slopes or flat ground. This makes it easier to work when the boom is sideways and gives the operator a larger working area.

The new trade dress is designed for the operator by BMW Design Works. In both harvester models the engine has been turned 180 degrees, the hydraulic oil and fuel tanks and the pumps have been placed in front of the engine, and the fan is at the rear of the machine. All this makes for a very quiet cabin.

1270H

- Powerful, all-around harvester

- IBC as standard

- H7 boom with high lifting and slewing torque

- Easy service and maintenance

- Large selection of harvester heads

- Excellent visibility to the working area

1470H

- The most capable harvester for large trees

- IBC as standard

- H9 boom with high lifting and slewing torque

- Easy service and maintenance

- Large selection of harvester heads

- Excellent visibility to the working area

Harvester head H216 for big harvesters

John Deere H216 is a new large harvester head for hardwood and softwood. It’s productive and easily customized to different needs.

H Series forwarders 2010H and 2510H

The new, large size-class 20-ton and 25-ton forwarders offer 25% more load capacity. The new twin motor driveline in the 2510H forwarder also offers a 50% faster driving speed. The twin motor driveline is also available for the 2010H forwarder.

Sales of H Series forwarders begin in 2025.

Powerful booms

The new F9 and F10 booms offer more power and longer reach. The reach of the F10 boom is 10.2 meters. The F9 boom has a reach of 10.7 meters. The hydraulic hosing and hose routings have been improved. The new F10 is the strongest forwarder boom in the market. With the 40% increased boom lift torque and 22% higher slewing torque, larger grapple options become available. The new F9 boom has 13% more boom lift torque and 10% more slewing torque.

Intelligent Boom Control IBC 3.0. as standard

IBC 3.0 becomes standard in the large H Series forwarders.

With IBC 3.0, at the push of a button the boom is automatically folded to the transport position into the load space and unfolded from the transport position. The boom also automatically returns from the pile to the load space with a push of a button.

Increased load capacity and expanded load area

The new forwarders have an increased load capacity and an expanded load area with two new size options with extendable bunks.

The 7.5m² load area option is optimal for handling heavy hardwood and eucalyptus logs, while the 8.5m² load area is recommended for the 2510H model with softwood.

2010H

- Large forwarder with 20-ton load capacity

- New F9 and F10 booms with more power and longer reach

- New frame lock brings more stability, even with full load

- IBC 3.0 as standard

- Easy service and maintenance

|

Max engine power, kW 220 |

Slewing torque, kNm 50/45 |

2510H

- Largest forwarder with 25-ton load capacity

- 50% faster speed of driving with the new twin motor driveline

- New F9 and F10 booms with more power and longer reach

- New frame lock brings more stability, even with full load

- IBC 3.0 as standard

- Easy service and maintenance

| Max engine power, kW 252 Engine torque, Nm 1550 Tractive force, kN 290 Boom reach, m 8.5/10.2/10.7 |

Slewing torque, kNm 50 Load capacity, ton 25 Load space options, m2 6.5/7.5/8.5 Turning angle, deg 44 |

For more info, contact your local dealer