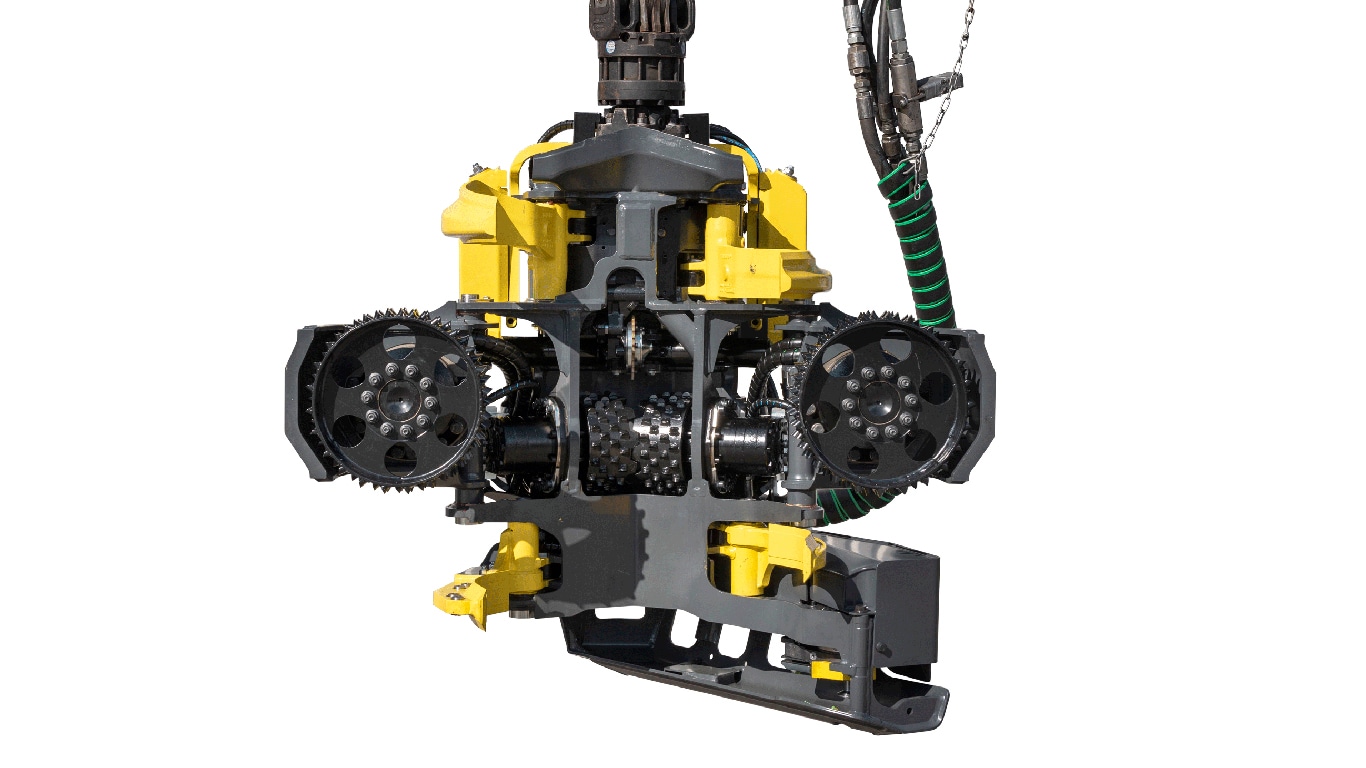

4WD harvester head H424

Excellent performance

The H424 is a 4WD harvester head with excellent performance, adjustability, control and economy. Durability is improved through hose routing, and ease of service with location of grease points and hinged valve block cover. Greasing intervals are also longer.

New optional HD tilt frame available.

Improvements to the predecessor

- New PEVO valve block for improved economy, adjustability and control, feed motor durability and productivity

- Hydraulic hoses from the loader to the harvester head and from the valve block to the feed motors have been rerouted to increase service life and facilitate hose replacement

- Backwards tilt angle is greater

- Placement of rear delimbing knives has been changed

- Frame load-bearing capacity has improved when feeding backwards

- Handling of crooked stems has improved

- Color marking from rear knife is more accurate

- Jump-offs of saw chain have been reduced

H424 tech specs

- Weight 1100 kg

- Max. felling diameter 620 mm

- Max. feed roller opening 640 mm

- Feeding speed 4,3-5,3 m/s

- Feeding force 27 kN

- Suitable base machine 1270G 10 m and 11.7 m reach

Over-rotation prevention protects against hose damage.

Over-rotation prevention is available for 1270G and 1470G harvesters with IBC 3.0 and H424 or H425/H425HD harvester head.

John Deere H424 harvester head at work

John Deere H424 harvester head at work