NEWS RELEASE October 24, 2022

SPFH benchmarking exercise proves John Deere advantage

As part of its commitment to delivering the best possible equipment to forage customers, John Deere undertakes factory and infield testing of its Self-Propelled Forage Harvester every two years to benchmark performance against both previous John Deere models and competitor equipment.

The latest round of testing was held in Italy's Autumn 2020, and examined the John Deere MY23 9700 SPFH, fitted with the new JD 18X engine, against the John Deere MY20 9700 and the Claas Jaguar 970 (502).

John Deere ensured the machine specifications were as similar as possible, however, the John Deere machines were installed with 56-knife cutterhead, opposed to a 64-knife cutterhead - the correct equivalent to the Jaguar 970's 36-knife cutterhead. This variation should have given the Claas a theoretical advantage when set to cut at short length.

Engine capacity

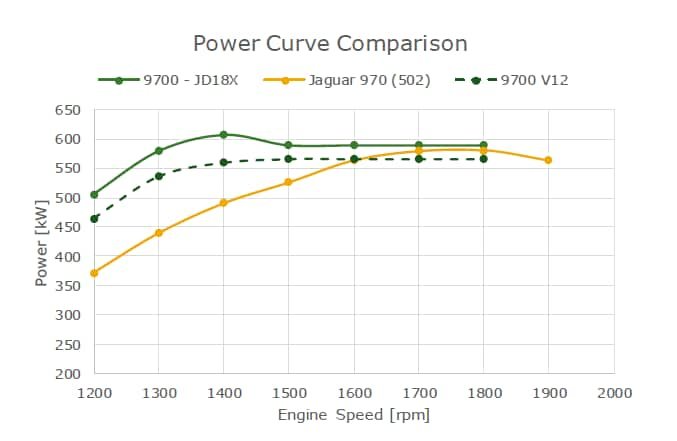

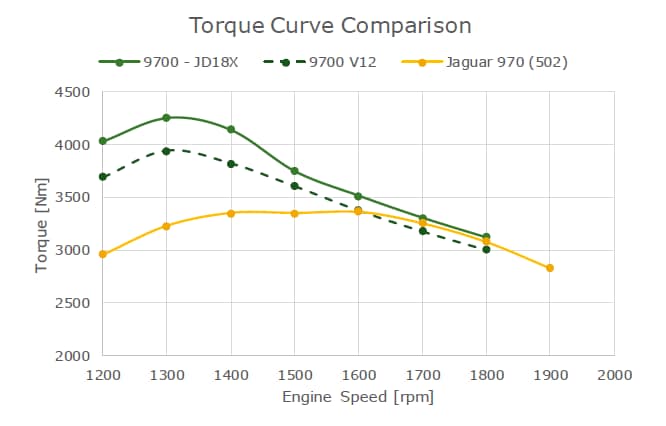

There was a clear focus on engine capacity, as John Deere looked to assess the new 18 litre, JD 18X engine in workshop conditions on the engine dynamometer.

This round of testing demonstrated the John Deere MY23 9700 offered strong torque rise and constant maximum power in the 1300 to1400 rpm range. This provides farmers comfortable and highly efficient operation at lower engine speeds. In contrast, the Claas machine was difficult to operate below 1700 rpm, due to having dramatically less power available.

Infield testing

Infield testing took place on a dairy farm, where the machines were challenged with harvesting a 35 hectare corn crop, over two days.

At four metres tall, the crop produced a yield of 65 to 95 tonne per hectare and was planted on flat, irrigated terrain. Weather conditions ranged from 30 to 35 degrees Celsius, and was hot and humid, with some heavy rainfall. Dry matter was recorded at 25 to 32%.

Productivity of the machines was tested in tonnes per hour, with length of cut (LOC) a key variable tested as part of the study. When the machines were test at a 10mm LOC, the MY23 9700 achieved a throughput of 282 tonnes per hour compared to the Claas, which achieved 260 tonnes per hour. This equates to an 8.4% advantage for the 9700 in this length of cut.

Fuel efficiency was also tested. John Deere engines, unlike Claas, don't require diesel exhaust fluid (DEF), immediately reducing an input consideration for farmers.

Efficiency was measured by litres of fuel and DEF per tonne harvested. Again, the MY23 harvester outperformed. At 10 mm LOC, both the Claas and the 9700 used 0.47 litres of diesel per tonne harvested, however the Claas required an additional 0.04 L of DEF per tonne, providing the 9700 with -7.8% less fluid consumption. For farmers this means significantly lower input costs.

John Deere advantage

This year, marks John Deere's half-century commitment to supporting the global agriculture sector with industry-best forage harvest solutions.

John Deere continues to invest in and lead innovative harvester solutions to deliver more power, precision and productivity and ensure its farmers are among the most productive, profitable and sustainable in the world.

About John Deere:

Deere & Company is a global leader in the delivery of agricultural, golf & turf, construction, and forestry equipment. We help our customers push the boundaries of what's possible in ways that are more productive and sustainable to help life leap forward. Our technology-enabled products including the John Deere Autonomous 8R Tractor and See & Spray™ are just two of the ways we help meet the world's increasing need for food, shelter, and infrastructure. Deere & Company also provides financial services through John Deere Financial. For more information, visit John Deere at its worldwide website at JohnDeere.com or in Australia at JohnDeere.com.au.