Hagie™ STS Sprayers Versatility & Application Quality

Turning Technology into Application Quality

Our sprayers turn technology into application quality, with the precision and consistency you need from start to finish. Best of all, these features automate application, so you don’t have to manually turn on and off nozzles or sections, making it easier for you to operate your sprayer.

Chassis

The Hagie chassis enables full-season versatility. With the tank centred in the machine, weight is distributed evenly across all four tyres for stability in damp spring fields. And the front-mounted boom enables late-season application.

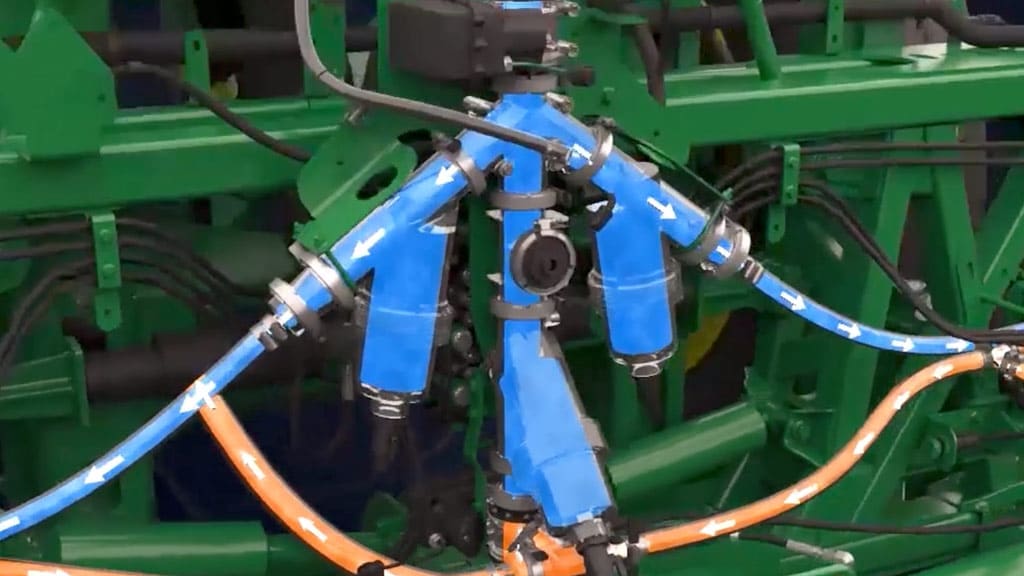

Pressure recirculation and air purge system

Save time and improve spray quality by keeping chemicals in suspension – even when the machine is on but not spraying. Pressure recirculation keeps chemicals in suspension so the boom is constantly primed and ready to spray. The air purge system removes air in the boom before spraying to improve the rate control at start of spraying.

ExactApply™ nozzle-control system

The optional ExactApply system reduces overapplication and thus crop burn, as well as off-target drift. The individual nozzle control has up to 30 hertz pulsing frequency and A-B nozzle design to help decrease overlap, improve efficiency and reduce input costs by 2 to 5%1. Two application modes give you more consistent droplet size from each nozzle at all sprayer speed ranges.

NORAC™ UC7

Offering consistent spray height to target for better coverage and efficiency. NORAC™ UC7 active wing roll simulates roll while reducing overall machine weight and system complexity.

Booms

The Hagie Hybrid boom provides strong, lightweight and versatile options to meet customers needs. Available in a variety of sizes, hybrid booms utilise both steel and aluminum. This Hybrid construction allows the booms to remain strong and flexible in the inside and lightweight at the extremities. This weight pattern reduces inertia and pull on the chassis.

Solution command system

Automate tasks from the filling station with the Solution Command System. The 12-button keypad provides quick and easy operation at the load station for operators of all skill levels.

PowrSpray

Reduce fill time with the PowrSpray option. With a load pump that fills up to 1135 L/min. (300 gpm), the STS 20 can be filled in seven minutes and STS 12 in four minutes. Products can be mixed onboard with the optional 18.9 L (5 gal.) poly eductor.

1Factory study comparing chemical usage between sprayers equipped with and without the ExactApply nozzle-control system. ExactApply is an optional feature and can reduce chemical usage from 2 to 5%. Individual results may vary.