Find & Order Parts

Look up part numbers and find diagrams to help identify the part you need.

Do Right by Your Ride On. Get it Serviced Today.

Home Maintenance Kits

Tune up your equipment with confidence and ease with our Home Maintenance Kits. Easily find the right product so you can do-it-yourself and save!

Quick Reference Guides

As a John Deere owner, when it's time to maintain, service or repair your equipment we have easy-to-use information sheets that keep your John Deere equipment running well.

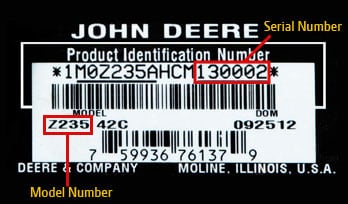

Looking for your Serial Number?

Finding your lawn mower’s model number and serial number is as easy as locating the identification tag on your machine. As seen in the example, the model number will be displayed below the MODEL heading (Example: Z235), and the serial number will be underlined on the top-right corner of the tag (Example: 130002).

If you're looking for the engine number, that can be found directly on the engine itself.

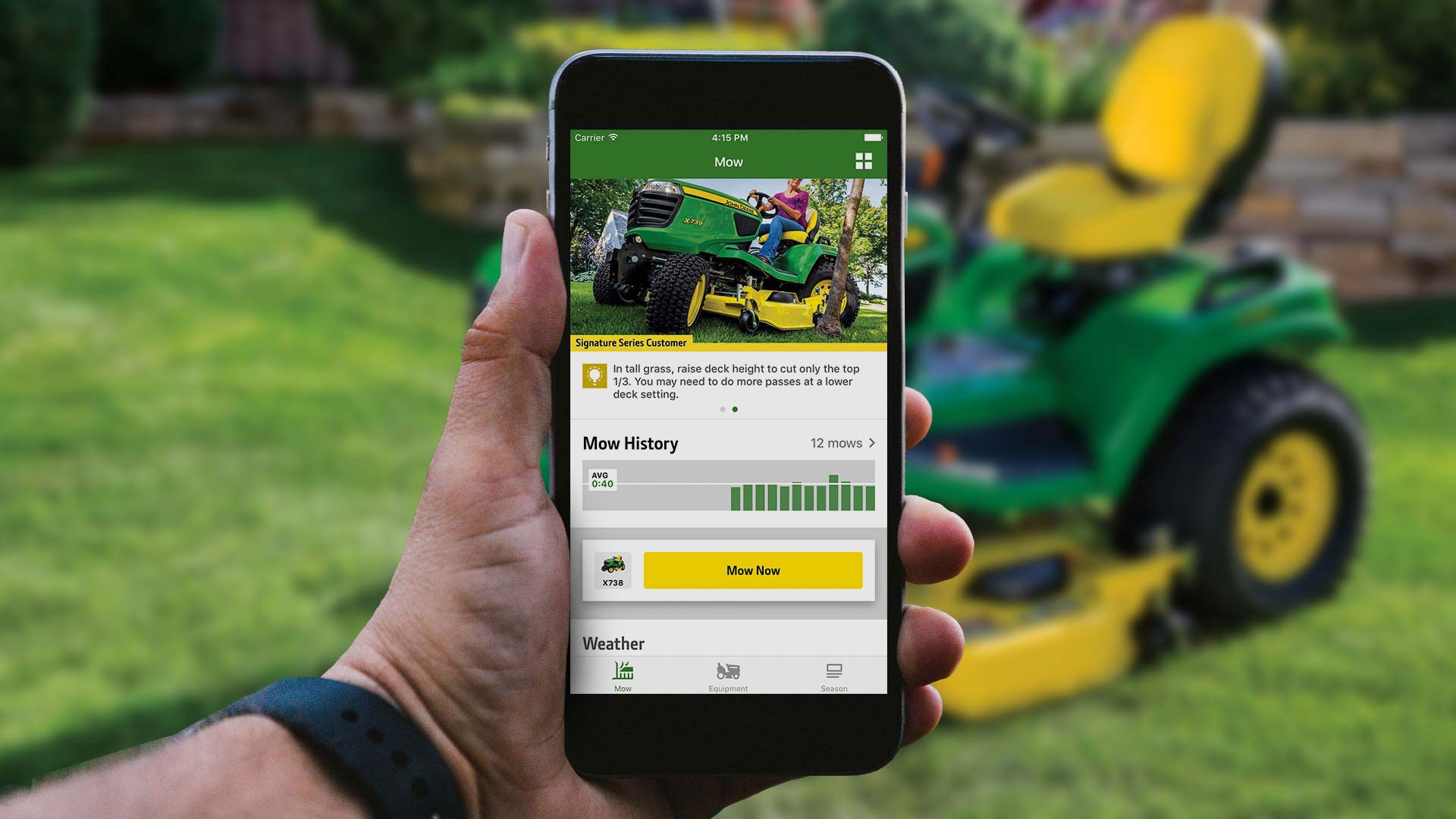

MowerPlus Mobile App for Mowing

MowerPlus is the app you need to keep your John Deere riding mower running well and your lawn looking great this season. It tracks and records yard tasks and serves as a one-stop shop for seasonal care tips and maintenance activities. Know your mower and know how you mow with John Deere's MowerPlus app.

Additional Information

Tackle Every Task

From bagging the big buck to tackling the nastiest trails, we’ve got the tools you need to equip your Gator for every outdoor adventure.

You take pride in your yard. So whether you’re striping your lawn for that professional look in the Spring, or bagging leaves come fall, we've got the attachments to help you get the job done.