Built for Aussie growers. Backed by your insights.

When we set out to reimagine our revolutionary cotton harvesters, we didn't start with a machine — we started with you. Cotton growers told us what matters most: faster harvesting, lower costs, and uncompromising reliability.

So we went back to the drawing board and engineered two of the most advanced cotton harvesters available today — purpose-built to meet the demands of Australian cotton country.

Everything you want. And more.

Sure, we built new row-units, a new power-unit, we redesigned the module building and handling system, and a lot more. But at the end of the day, it's the bottom line that counts. And these machines deliver serious cost savings at harvest time1.

Click Icons Below To Learn More

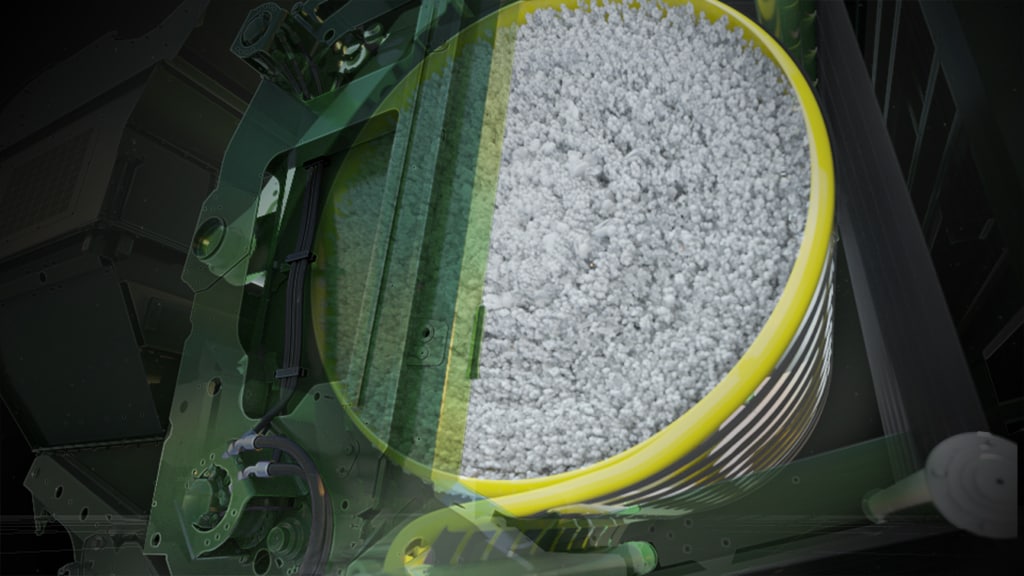

Cotton Module Building and Handling

Save up to 12% on Wrap and Hauling

To help maximise cost efficiency, we redesigned the round module builder as well as the wrapping and handling system; both the CP770 and CS770 now pack more cotton into each module, reducing the cost of module wrap and module hauling.

Improved wrap feeding

Experience consistent wrap feeding, module after module, with the new positive drive wrap system, operators will appreciate the reliability of the system, along with the simplicity of loading.

Denser bales = less wrap per kilogram

Cotton picker operators: the new CP770 delivers a solid 8% saving in wrap and transport costs per kilogram of lint compared to the previous model. For stripper growers, the CS770 offers an even greater benefit — reducing wrap and haulage costs by 12% per kilogram of lint.

Reduced module wrap time

Our next-generation module handling system cuts the module wrap-eject cycle time by 33%, from 48 seconds to 32 seconds, allowing you to stay at harvest speeds longer, and making every harvest day more productive.1

Increase turnout with improved cleaning

Reduce your seed cotton losses with the high-capacity three-drum onboard field cleaner. 2Independently tested, results show a 10% increase in cleaning efficiency3 and removes more plant material in the field - reducing your wrapping, hauling, and ginning costs.

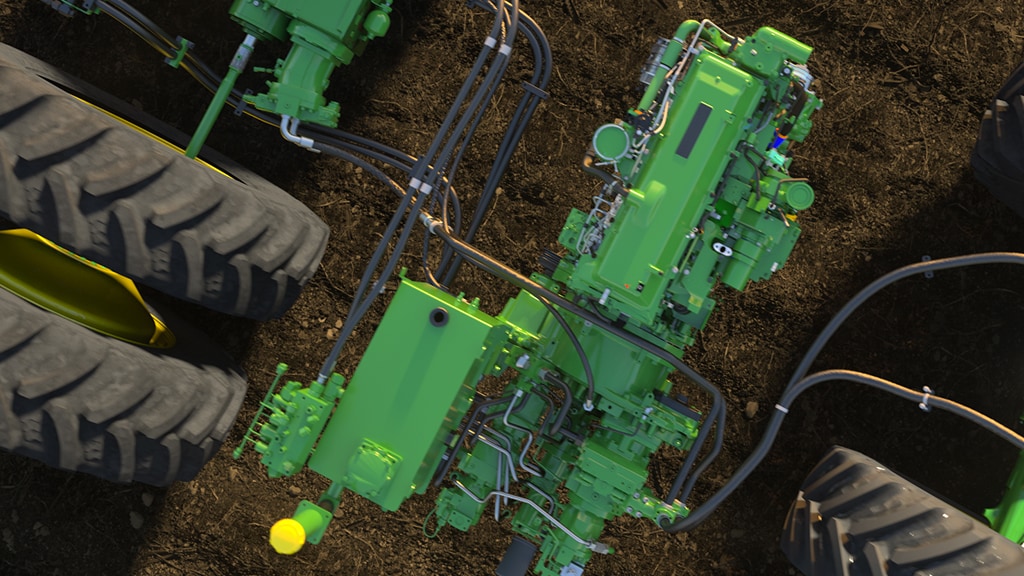

Engines and Hydraulic Power

Efficient, Quiet, Usable Power

At the heart of the C770 Series is the John Deere 13.6 L PowerTech™ engine, tuned to deliver the power you need, when you need it, with less fuel consumption, lower noise levels, and higher transport speed.1

Increased Fuel Efficiency

Improved fuel efficiency lets you harvest more with every litre. The CP770 uses 20% less fuel than its predecessor, while the CS770 uses 15% less fuel than the previous stripper.

Higher Transport Speed

You and your operators will appreciate the increased transport speed…you can run from field to field at 32.2 km/h, up from 27.4 km/h over previous models.

Reduced Noise

With the engine working at an easy 1,900 RPM, you'll notice reduced noise in the cab…3 dBA less in the CP770, 5 dBA less in the CS770.1

Reduced Complexity

We've redesigned the engine and hydraulic power module to use fewer unique parts, reducing complexity and improving maintenance and serviceability.

Cotton Picker Row Units

Pick Another 1.8 Hectares per Day

You know better than anyone — the longer cotton stays in the paddock after defoliation, the more the lint quality drops. That's why we've upgraded our proven row units to help you move faster and get out of the paddock sooner.

New direct-drive gearboxes

Direct-drive gearboxes in the new PRO16 HS Row Units deliver smooth, efficient power, while contributing to overall fuel savings, and reducing maintenance and complexity.

Harvest Speed

The PRO16 HS Row Units allow for a 5% increase in picking speed, to 7.4 km/h, compared to 7.1 for our previous row units. That means you can harvest an additional 1.8 hectares during a typical 10-hour harvest day.

Stalk Lifters

New high-speed stalk lifters gently transition the crop into the row unit's picking zone, reducing boll loss and enabling the PRO16 HS units' higher picking speeds.

Cotton Stripper Headers

Stripper cotton growers — ready to cover more hectares each day?

We've got the solution: the new SH12F Folding Stripper Header. Designed with serious productivity in mind, this header makes it easier to harvest more, faster. It folds quickly for transport and features a redesigned attachment system for faster, simpler hook-up in the paddock.

12-Row folding header

The new SH12F 12-row Folding Stripper Header lets you cover 48% more hectares per hour than an 8-row header on our previous stripper. The SH12F folds in under a minute, and can be transported without removing it.

Three available headers

The SH12F joins our SH8R 8-row and SH12R 12-row rigid headers to create a complete lineup of stripper headers. The SH8R can accommodate 91.4-, 96.5-, and 101.6-centimetre rows; the SH12R can handle 76.2-, 81.3-, and 91.4-centimetre rows, while the SH12F takes on 96.5- and 101.6-centimetre rows.

Improved Header Hookup

When you do need to attach and de-tach the header, new no-tool hydraulic hook-up cuts the time in half, to an easy-to-handle 15 minutes.

Comfort and Convenience

30% Larger Cab

From the shock-absorbing ActiveSeat™ II to the hard-driving sound system, we have the standard and available features you need to build the harvest-time office of your dreams. We'll start with a cab that not only has 30% more space than the previous harvesters, but also features familiar, automotive styling, head-to-feet HVAC ducts, a display that swivels with the seat, and plenty of USB ports for your devices.

ActiveSeat™ II Suspension

ActiveSeat II Suspension reduces vertical seat motion by up to 90 percent, as compared to an air-suspended seat. Standard with Ultimate Cab Package.

Touchscreen radio

Available in our Premium and Ultimate Cab Packages, the touchscreen App Radio lets you listen to your favourite music, podcasts, or audiobooks. Two speakers plus a subwoofer give you the ultimate audio experience.

Foot rests

Take a load off and get comfortable with our foot rests, available in the Premium and Ultimate Cab Packages.

Refrigerator

Order our Premium or Ultimate Cab Package, and you'll get a roomy fridge, perfect for keeping lunch and drinks cold.

Technology

The most complete tech package available.

Your guidance, mapping, tracing, data-sharing, and remote-diagnostic capability begins with the integrated G5Plus CommandCenter™ Display and StarFire™ 7500 Receiver; from there, our standard technology products and applications help you, your consultants, and your ginners make informed decisions that maximise productivity and profitability.

JDLink™ Connect

The C770 Series comes with JDLink Connectivity, giving you easy communication with your machines, your operators, and and your dealer. Analyse progress and performance, transfer data to and from machines, and use Machine Alerts and Service ADVISOR remote to pre-empt or diagnose issues.

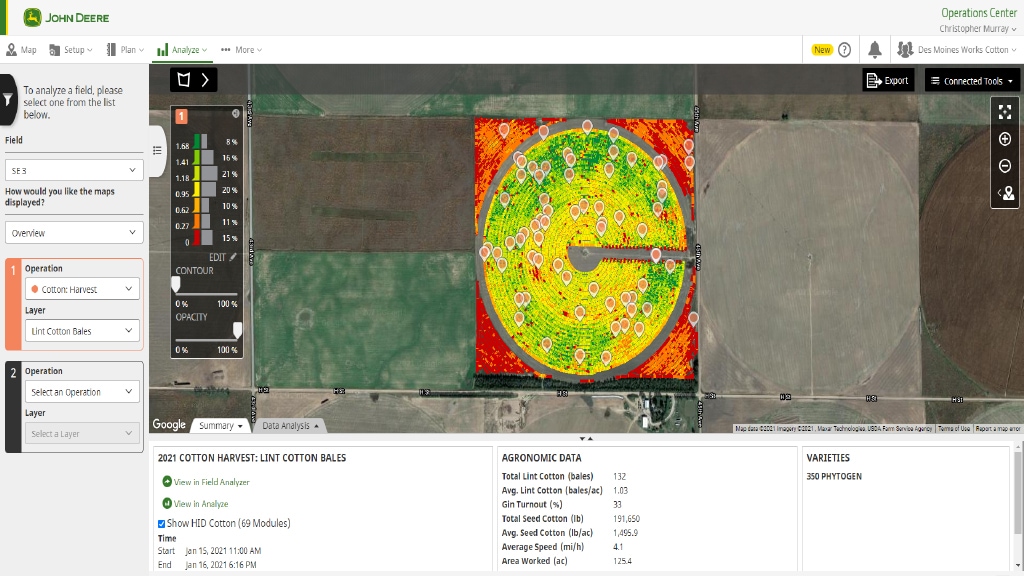

John Deere Operations Center™

Access field, crop, and machine information anytime, on your desktop computer or mobile device, through John Deere Operations Center. Plus, with more than 190 connected software tools, including major farm management systems, you can make the most out of your data.

HID, Cotton Pro

Capture, analyse, and share harvest information down to the module with Harvest Identification, Cotton Pro. Track module moisture and weight, then share that information with your gin to help prioritise module movement. Together, Harvest ID and Cotton Pro allow for traceability from the field to the end use.

RowSense and AutoTrac Guidance

Stay on track with Row Sense and AutoTrac Guidance, both standard from the factory. RowSense uses mechanical sensors to guide you through standing crop; AutoTrac then provides secondary GPS guidance to help steer through any gaps. Together, they offer the most accurate guidance available.

Documentation and Field Analyzer

Make informed decisions using data from the Documentation and Field Analyzer applications. Track your yields from field to field, then generate and share detailed yield maps with your consultants, seed reps, agronomists, or other advisors through the John Deere Operations Center.

Maintenance & Reliability

Our equipment is supported by one of the most responsive dealer networks in the business.

John Deere Connected Support™

Cotton Harvesters come with built-in technology to sense potential issues and alert you - or your dealer - when there's a concern. With Connected Support, you get Remote Display Access and Expert Alerts. You can monitor machine fuel levels, location history, receive alerts and view the in-cab display remotely.

Inspections

Keep your cotton harvesters in tip-top condition with comprehensive inspections. The best-trained technicians in the industry will replace worn parts and tune up other key areas.

You Also May Be Interested In

1Internal John Deere comparisons between CP770 and CP690, and between CS770 and CS690. Individual results may vary.

2Internal John Deere comparisons between CP770 & CP690, and between CS770 and CS690 equipped with FT4 engine. Individual results may vary.