Up to 70% more capacity in high yielding wheat

You have a tight harvest window and an even tighter profit margin. You need more productivity and low losses. You need a combine that can get as much done in a day as you need it to — day in and day out, season after season. You need an X9 Combine. These combines deliver an average of 45% more harvesting capacity across all crop types, with no sacrifice in grain quality — all while using 20% less fuel.1

Automation

Predictive Ground Speed Automation

The optional Ultimate Technology Package includes Predictive Ground Speed Automation. Using two forward, cab-mounted stereo cameras, the X9 constantly measures crop height and volume – while pre-harvest satellite field images generate a predictive field map. The combine takes this data and automatically adjusts ground speed BEFORE entering changing crop areas. Feel confident to maintain peak feed rates all day long, even in inconsistent crop conditions. That helps you increase combine capacity while minimising grain loss.

Harvest Settings Automation

Harvest Settings Automation – included in the Premium and Ultimate Technology Packages – makes it easier than ever to set the specific outcomes you expect. Using your G5Plus Display, simply set acceptable limits for grain loss, foreign material, and broken grain. Once set, the combine automatically adjusts itself to deliver the performance you want. No more manually adjusting rotor speed, fan speed, and concave, chaffer, and sieve clearances. The combine does it for you according to outcomes you've already prescribed. That gets you into crops faster and reduces the things you have to constantly monitor.

Capacity

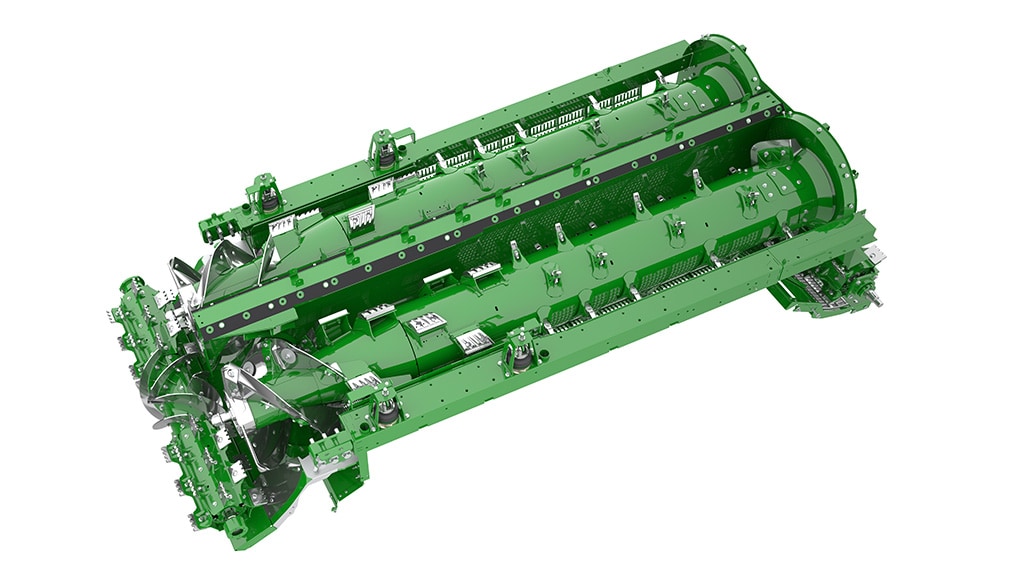

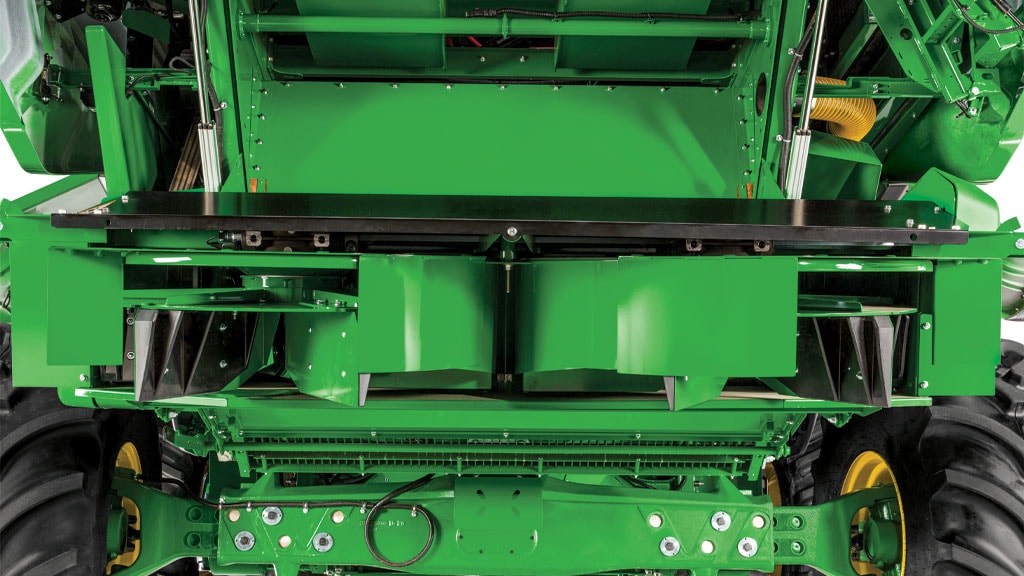

Dual separator

Two 60.96 centimeters (24-inch) rotors with an increased threshing area of 45% and separating area of 80%4 for better threshing and separating in high-volume crops.

Cleaning shoe

New shoe offers 36%1 more cleaning area to effectively put clean grain in the tank in the toughest harvesting conditions.

Bigger on the inside

Even with 45% more threshing area4, and 80% more separating area4, the outside dimensions are about the same as the S7 900, for tight turns and narrow transport.

Efficiency

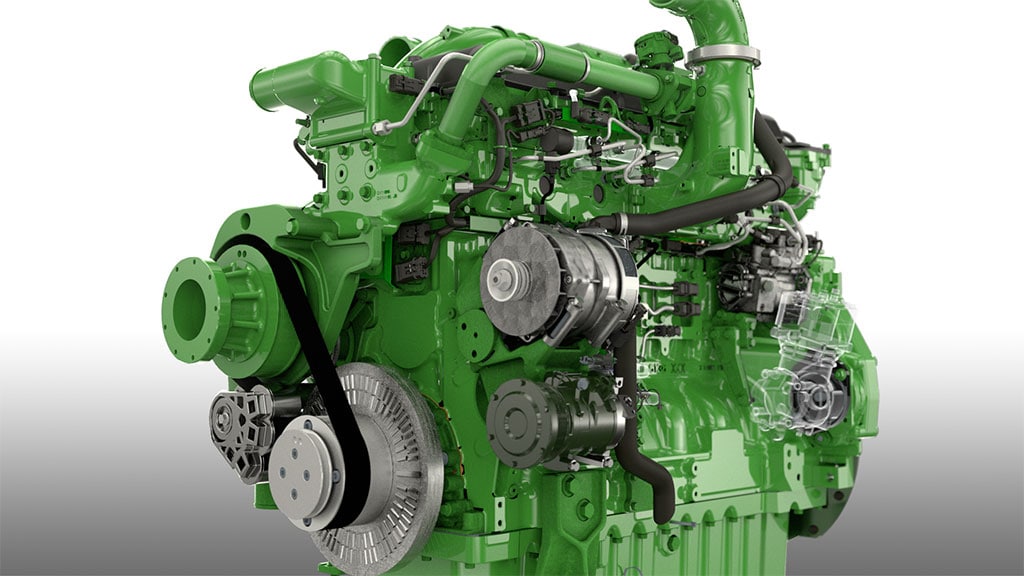

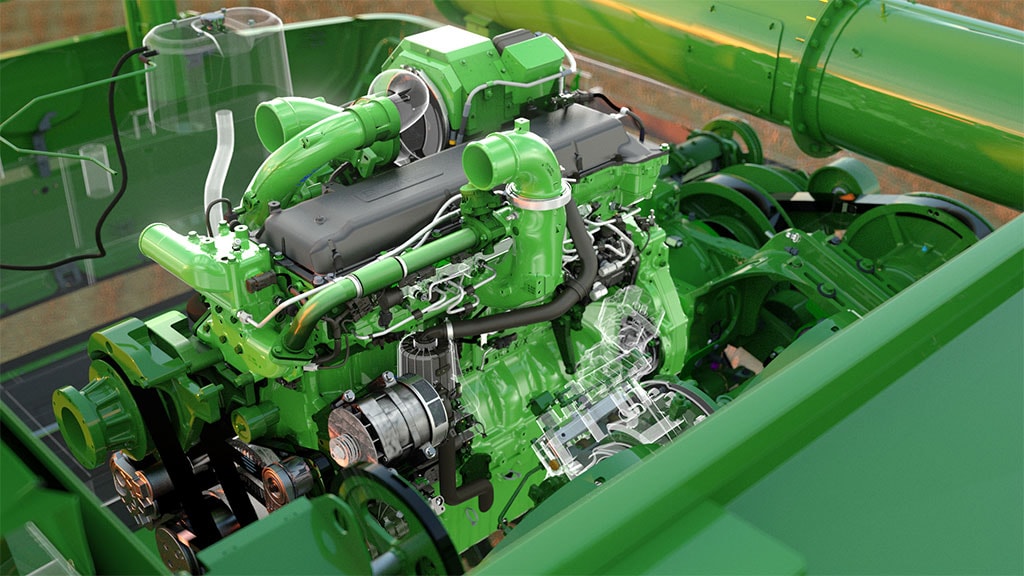

A more efficient engine

A new John Deere 13.6-litre engine delivers up to a 45% increase in harvesting capacity, while only needing 11% more horsepower than an S7 9001.

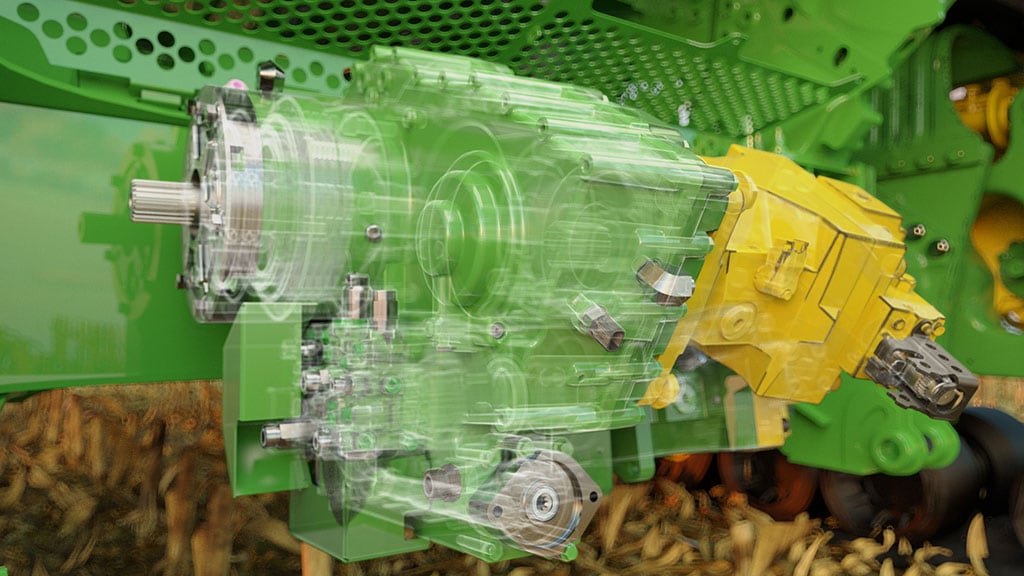

Seamless speed control

30%2 more torque to handle larger loads with a smooth power increase with the new ProDriveTM XL transmission.

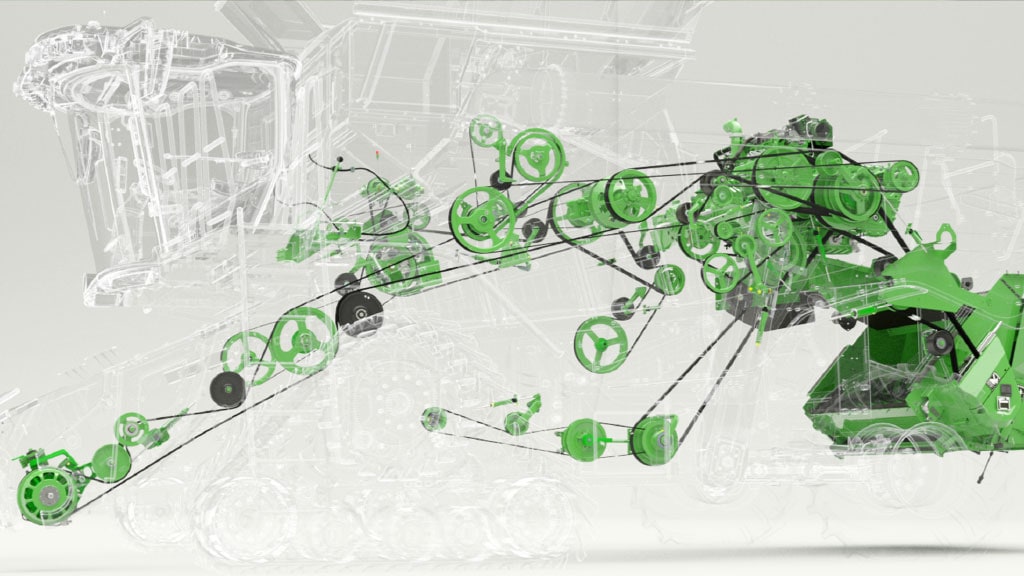

Belt-drive system

Our simplified belt-drive system uses larger pulleys and longer belts to improve the handoff of power and belt wear-life2.

20% less fuel2

It's not just the engine that delivers lower fuel costs, it's every aspect of the design. The belts, transmission, residue system, rotors, and lower RPM all play a role in saving you money on fuel.

Improved residue management

New system spreads up to 15.2-metres wide; the double-decker design provides better air flow for even distribution with less power consumption.

Versatility

Integrated intelligence

From the Integrated StarFire™ Receiver to JDLink™ Connectivity, the X9 Combine comes ready to make your harvest easier.

Get More in Rice

Gain resistance to the abrasiveness of rice, along with up to 65%5 more capacity while using 20% less fuel6 with the tough, wear-resistant X9 Rice combine package.

Choose from wheels or tracks

Tracks deliver improved floatation and allow for transport speeds up to 40 kilometres per hour.

Easy-change concaves

Lighter concaves make switching crops even easier.

Reduced plugging

The modulated feederhouse reverse allows the feederhouse to reverse under full engine RPM to reduce the chance of plugging in heavy crop.

In-cab control

With the G5Plus CommandCenterTM Display, you get in-cab control of the power folding unloading auger and adjustable spout for easier unloading and residue adjustments.

Headers and Platforms

X9 Combines are engineered to create a perfect balance between front-end equipment and machine power, so together they deliver stable, consistent performance with every pass, even in tough conditions.

Drapers

Belt Pickup

Corn Heads

More power, without more fuel use

X9 Combines have a new

John Deere PowerTech™ 13.6-litre engine, which delivers a 14% increase in power and an 11% increase in torque over the 13.5-litre engine. A high-pressure common rail system more efficiently injects fuel into the engine for additional fuel savings.

Maintenance & Reliability

Our combines are supported by one of the most responsive dealer networks in the business.

John Deere Connected Support™

Keep running. That’s job one of John Deere Connected Support. You can reduce downtime with connected tools that remotely monitor and proactively service your combine.

Inspections

Keep your combine in tip-top condition with comprehensive inspections. The best-trained technicians in the industry will replace worn parts and tune up other key areas.

1Internal comparison between X9 1100 and S790 Combines, based on field conditions, per-unit harvested. Pre-production model shown.

2Based on internal testing, performance claims based on field and crop conditions at the time of testing; individual results may vary.

3Semi-trailer trucks with 993-bushel capacity. Specifications and design subject to change.

4 Internal comparison between X9 1100 and S790 Combines, based on field conditions, per unit harvested.

5Internal comparison between X9 1000 and S790 Combines

6Internal comparison between X9 1000 and X790; results vary depending on field conditions.